Initial situation biomass power plant Friedersdorf

Sediments in the rotary piston pump / percolate pipe |

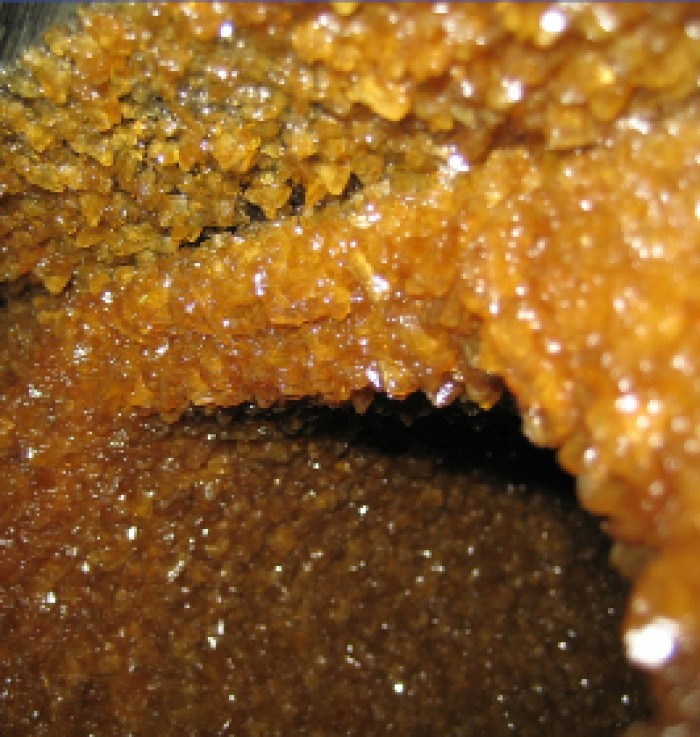

Sediments from the |

Sediments in the rotary piston pump / percolate pipe |

Situation after the installation

Due to the application of the Fluid-Liner® in the area of the suction and pressure pipeline, the lifetime of the system was significantly increased. The continuous percolate feeding to the biomass causes not only a higher gas yield by the same amount of nutrients used but also an improvement of the fermentationresidue and a higher concentration of the percolate. Thereby it was possible to operate the biogas plant in an economical way. After the optimisation the Fluid-Liner® was amortized during half a year.

|

|

|

| Fluid-Liner® system with a special high-power transformer (several places of treatment) | ||